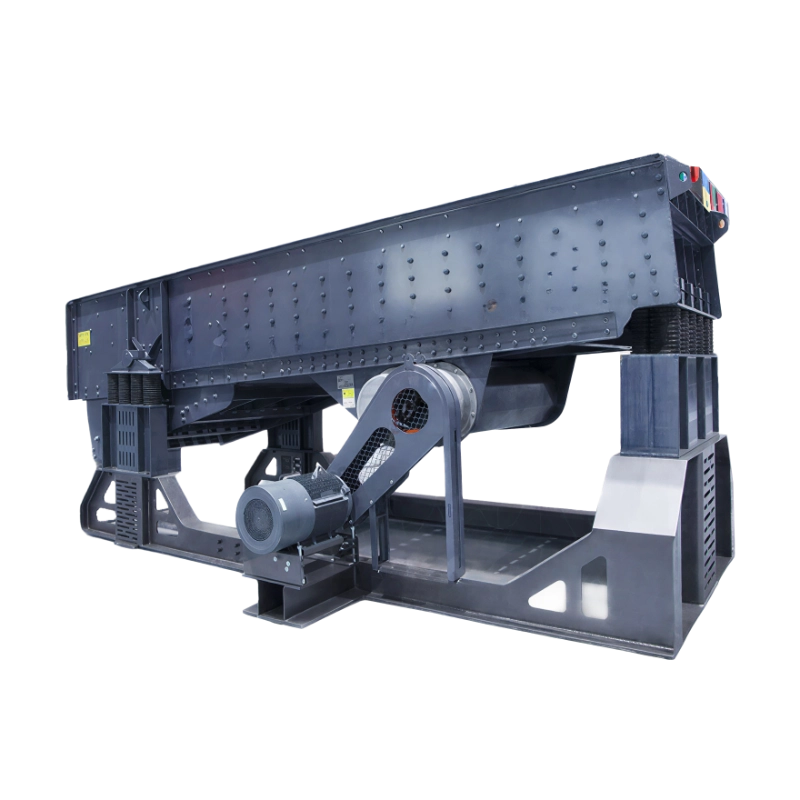

Maximize the efficiency of your primary crushing circuit with our premium Used Apron Feeder. Designed to thrive in the toughest mining environments, this heavy-duty plate feeder ensures a consistent, regulated flow of material to your primary jaw crushers, impactors, or cone crushers (such as the HST Series). unlike standard belt feeders, our used apron feeders are engineered to withstand extreme impact loads from dumping trucks and handle wet, sticky, or abrasive Run-of-Mine (ROM) materials without slippage. Thoroughly inspected for mechanical integrity and available at a fraction of the cost of new equipment, this unit offers a smart, cost-effective solution for quarries and mines requiring immediate deployment.

- Product Description

- FAQ

Performance Characteristics

in the rigorous world of material handling, the feeder is the heartbeat of the plant. This Used Apron Feeder is a robust, tractor-chain style feeder designed to extract or feed heavy, lumpy, or abrasive ores from storage bins or hoppers. It is specifically built to handle material that is too severe for belt feeders, ensuring your production line remains continuous and efficient. Whether you are processing hard rock granite, iron ore, or recycling concrete, this machine provides the torque and traction needed to move the mountain.

Why Buy Used?

Purchasing a used mining apron feeder is a strategic capital decision.

- Cost Savings: Acquire top-tier OEM engineering (such as Metso, Sandvik, or Terex equivalent quality) for 40-60% less than the price of a factory-new unit.

- Immediate Availability: Skip the 6-12 month manufacturing lead times typical for new heavy machinery. This unit is ready to ship and install, helping you ramp up production faster.

- Proven Reliability: Used equipment has a track record. This unit has been inspected to ensure the frame, drive, and pans are free from structural fatigue.

Key Features & Design

1. Heavy-Duty Pans (Flights) The feeder utilizes high-strength manganese steel or alloy steel pans. These overlapping pans are bolted to the heavy-duty track chain, creating a continuous steel belt that is virtually indestructible. The overlapping design prevents fines leakage, keeping the area under the feeder clean and reducing maintenance.

2. Rugged Drive System Equipped with a high-torque electromechanical or hydraulic drive system, this feeder can start under full load—a critical feature when the hopper is full of rock. The sprocket and chain design ensures positive traction, eliminating the slippage often seen with belt feeders in wet conditions.

3. Impact Resistance The frame is reinforced with impact rails or rollers designed to absorb the shock of falling rock. This makes it the ideal candidate for receiving Run-of-Mine (ROM) material directly from dump trucks or wheel loaders before feeding it into a primary Jaw Crusher or HST Series Cone Crusher.

Condition & Inspection Points

For a used unit, transparency is key. We focus on the vital components during our inspection process:

- Chain & Rollers: We check for link wear and roller seizure to ensure remaining service life.

- Pan Surface: Inspected for excessive bowing or wear.

- Sprockets: Teeth are checked for profile retention to ensure smooth engagement.

- Drive Unit: Gearbox and motor are tested for noise, vibration, and thermal stability.

Applications

This Apron Feeder is versatile and essential for:

- Primary Feeding: Regulating flow to Jaw Crushers or Gyratory Crushers.

- Secondary Feeding: Extracting from stockpiles to feed Cone Crushers (like the HST100-HST750 series).

- Difficult Materials: Handling wet clay, large boulders, and sharp, abrasive ores that would tear a rubber belt.

Conclusion

Don’t let lead times bottleneck your operation. This Used Apron Feeder combines rugged durability with economic sense. It is a workhorse ready to integrate seamlessly into your existing crushing and screening plant. Contact us today for a detailed inspection report, high-resolution photos, and a shipping quote to your site.

Why Choose Us?

-

1.Full Range of Equipment. Your One-Stop Source

We simplify your gravel & sand operations with full-process equipment from a single source, saving you time and effort.

-

2.Professional Service Guarantees Peace of Mind

Expert Maintenance Team + Genuine New Parts + Comprehensive Warranty for Stable, Continuous Production.

-

3.Transparent Inspection. Trusted Partnership

Check the interior conditions on-site. Buy with confidence.

-

4.Rich Experience

30+ years in the industry. Precise market insight,professional service.

-

QHow long does it take from order to delivery?

AFor equipment in stock, we can complete the internal inspection and loading within 7–10 working days. The sea freight duration depends on your destination port (e.g., 20-30 days to Southeast Asia or Africa). We will provide a clear timeline once the shipping route is confirmed.

-

QHow do I know the equipment is in good working condition?

APrior to shipment, we provide complete testing videos and live video inspections via WhatsApp or Zoom. This allows you to see the machine running in real-time. We also provide a set of high-resolution photos showing the critical components (motor, chassis, and wear parts) to ensure transparency.

-

QAre spare parts readily available for the equipment I purchase?

AWe understand that downtime is costly in mining operations. We offer a comprehensive spare parts support program for every machine we sell.

-

QWhat factors affect the price of a crusher?

AThe main criteria for judgment are based on a comprehensive assessment of factors such as the model, size, performance, and working efficiency of the crusher.

-

QSince you specialize in used machinery, can I customize or order a brand-new machine through you?

AYes, absolutely. While we are a leader in the secondary market, we maintain strong strategic partnerships with top-tier global manufacturers. We can facilitate the customization and procurement of brand-new mining equipment tailored to your specific project requirements. Whether you need specialized configurations or the latest models, our team can handle the entire sourcing and technical specification process for you.