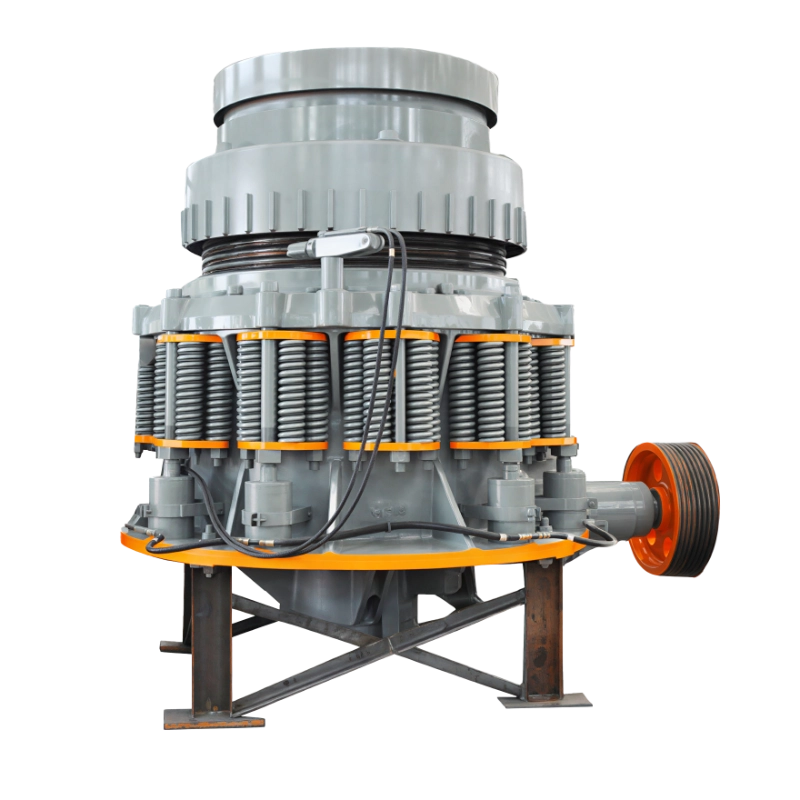

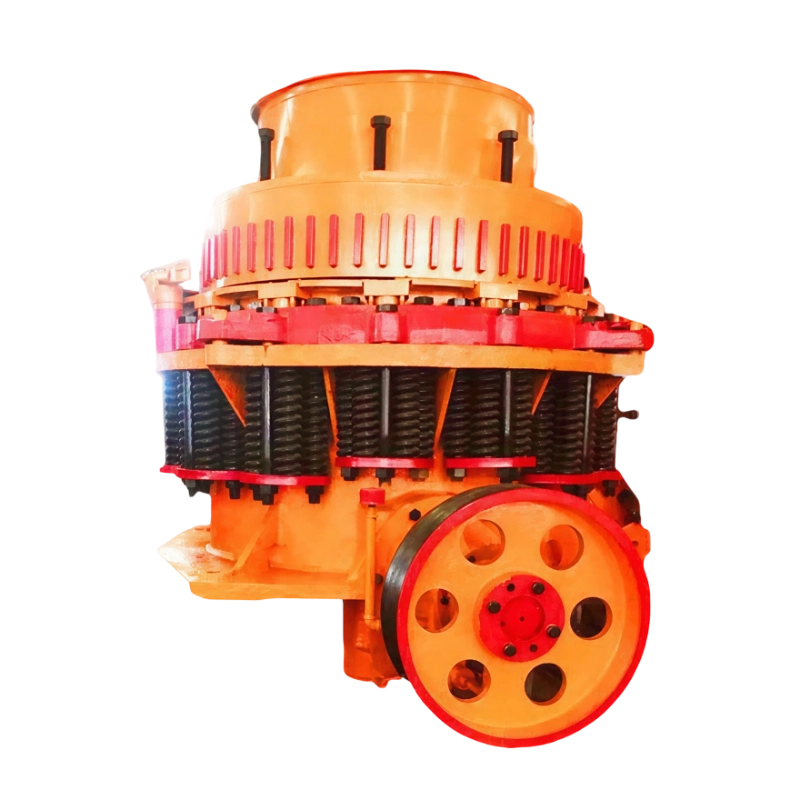

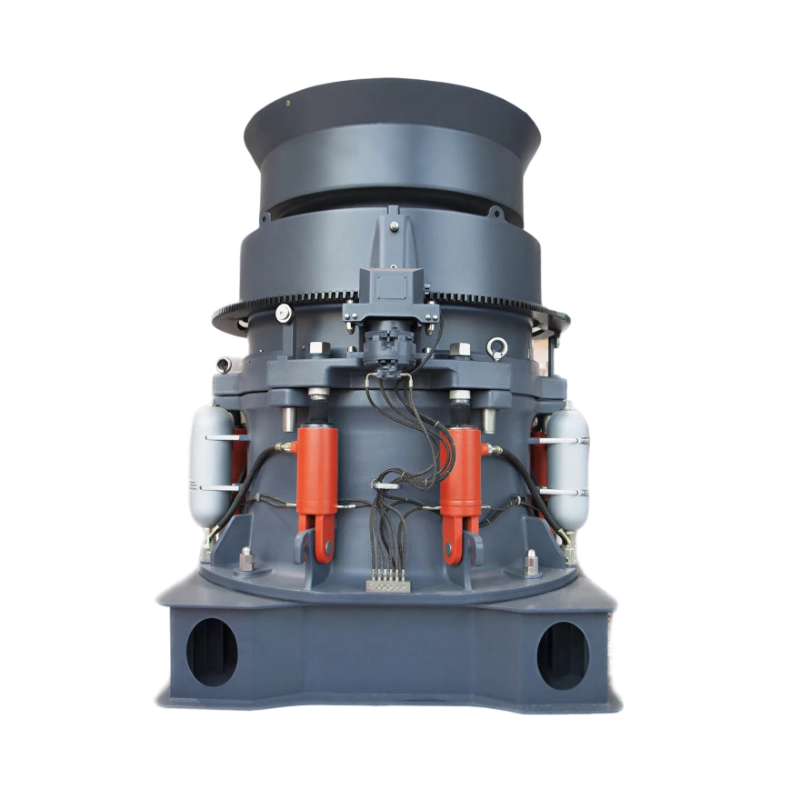

[Feed Size]: 80-300mm

[Production Capacity]: 80-610t/h

[Application Areas]: Mining ore, building material crushing, cement plants, sand and gravel quarries, concrete mixing plants, construction waste, dry mortar, chemical industry, etc.

[Applicable Materials]: Granite, basalt, limestone, river pebbles, iron ore, bluestone, quartzite, construction waste, etc.