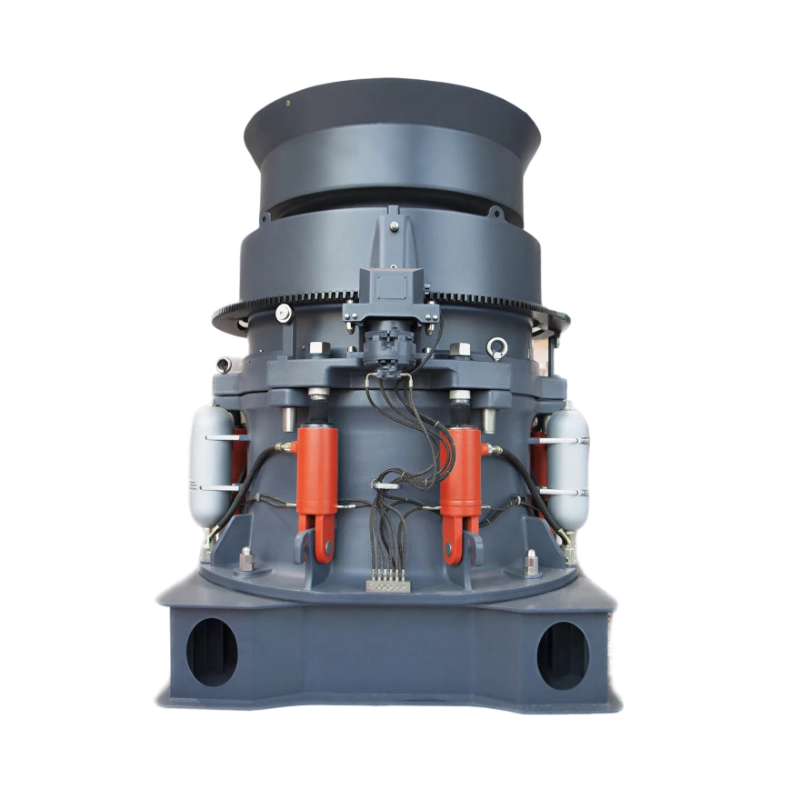

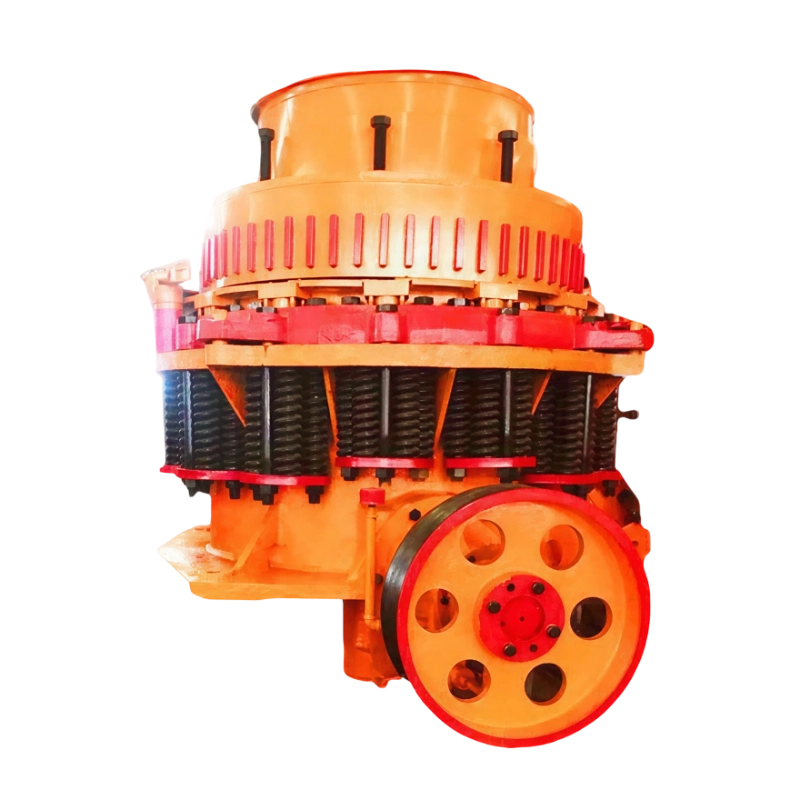

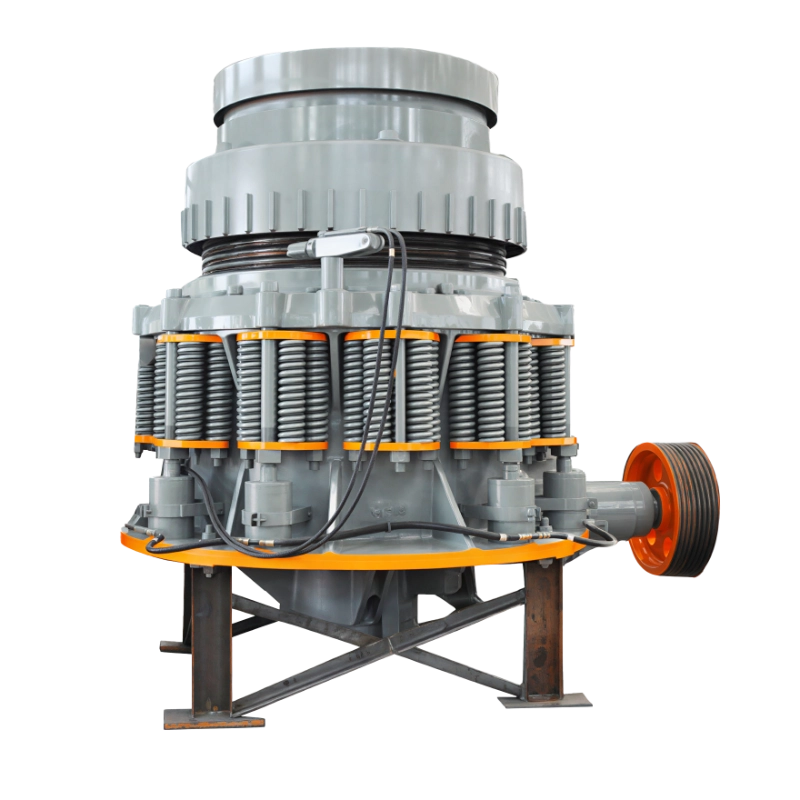

The Single Cylinder Hydraulic Cone Crusher represents the modern era of intelligent crushing. Distinguished by its compact design with a single hydraulic cylinder at the bottom, it offers a unique combination of simplicity and high-tech automation.

This machine is designed for steep-cavity crushing, providing high efficiency and a direct metal-to-metal crushing action. For used equipment buyers, finding a single-cylinder model is a major upgrade because:

-

Intelligent Control: Comes with a PLC system that automatically monitors load and adjusts the discharge setting in real-time to maximize production.

-

Easiest Maintenance: All maintenance is performed from the top; replacing liners is faster than any other cone type.

-

Superior Shape: The steep cavity ensures high inter-particle crushing for excellent aggregate shape.

It is the ideal choice for modern, automated plants where efficiency and product quality are paramount.