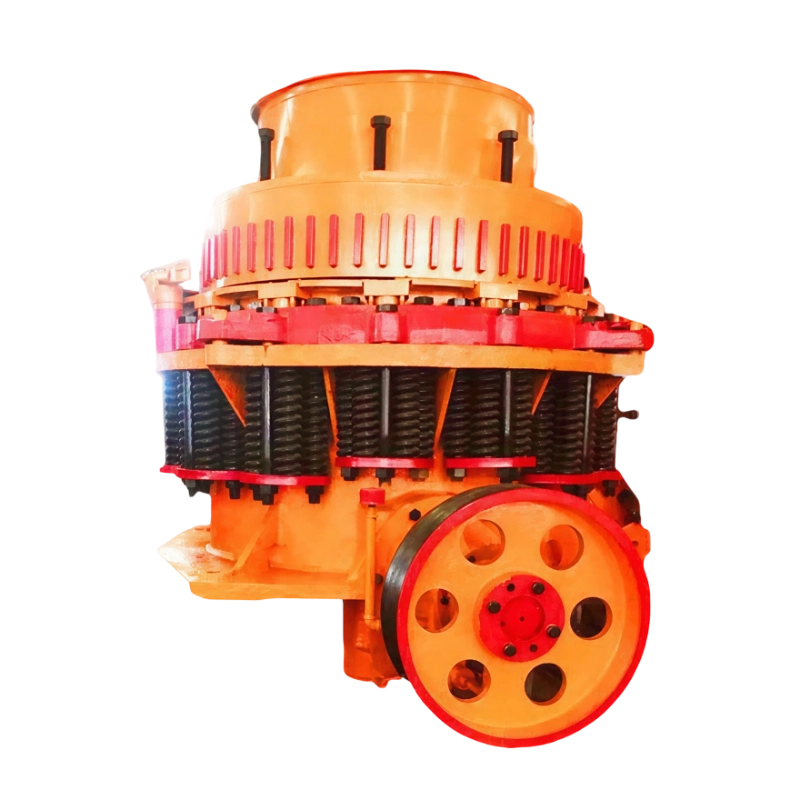

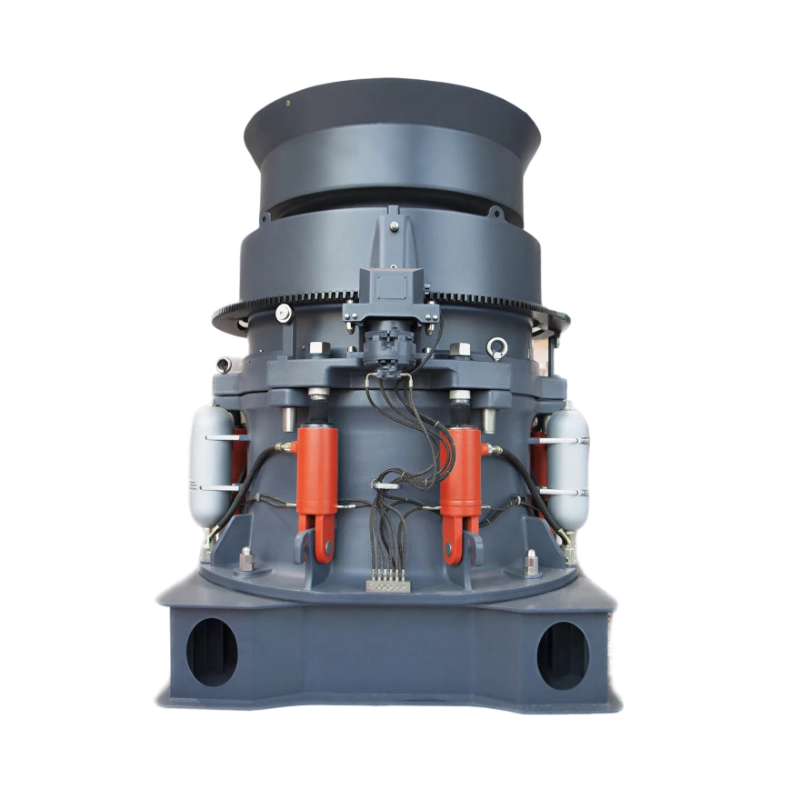

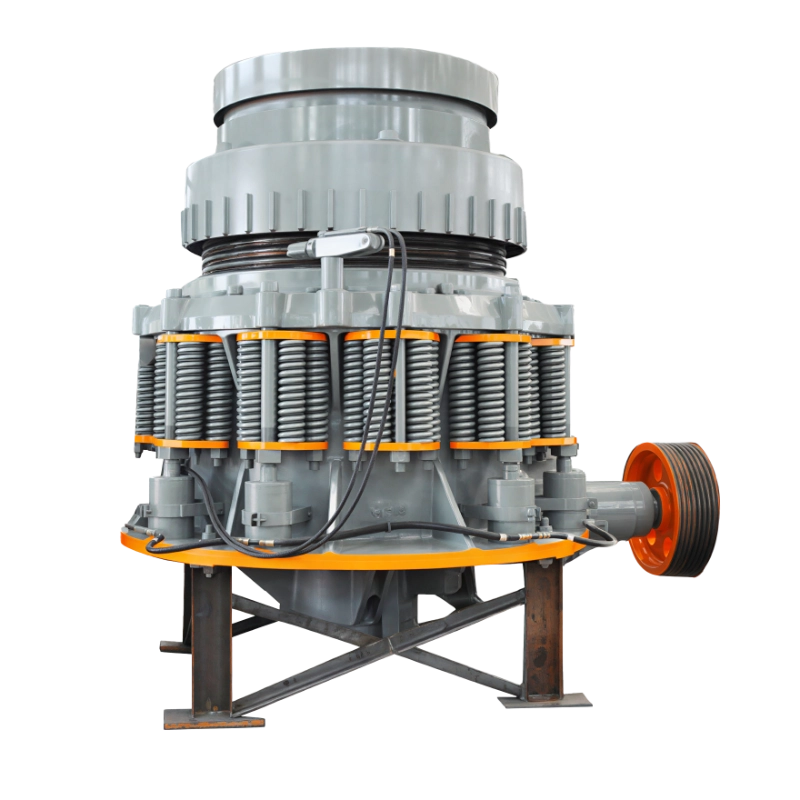

Study and research the evolvement of cone crushe,JBC compound cone crusher is our newly-exploited product,we own it's technical on the design of some advanced inside structures.It compounds the spring and hydraulic function together to achieve more efficiently procluciton.JBC cone crusher enjoys the structure characteristics of cast steel frame,heavy loaded part fixed with strengthening rib,both sides of driving shaft equipped with roller bearings,power system driven by heavy conical bearing,and there is a serve frame locking ring at the bearing block to avoid oil leaking out Besides,the hydraulic adjusting system makes it easy to change the discharge opening

- Product Description

- FAQ

Besides the”spring type overload protection”,JBC compound cone crusher also shows its special function of hydraulic cavity-cleaning,when the machine is stuck by big stone or other larger size particals,this semi-automatic system greatly reducing the downtime.The wearing parts installed with automatic locking structure,so reduces the time of replacing and installation,which increases the productivity.The external lubrication system will automatically turn off the machine if the oil temperature is too high or the speed of oilflow is too low,Moreover,users also can feel the thoughtful design,easy operation and maintenance at this JBC compound cone crusher

Main technical parameters

| Standard | Chamber | Max feed size(mm) | Min discharge opening(mm) | Motor power(kw) | Capacity | Weight(t) |

| Close discharge | ||||||

| 6 10 13 16 19 22 25 38 51 64 | ||||||

| JBC600 | C | 95 | 10 | 37–45 | 20 25 30 35 45 50 76 | 5.3 |

| M | 72 | 6 | 37–45 | 18 20 25 30 35 40 45 60 | 5.3 | |

| JBC1000 | C | 160 | 13 | 90–110 | 80 100 135 150 175 235 | 10.8 |

| M | 115 | 10 | 90–110 | 65 75 90 120 135 150 | 10.8 | |

| F | 80 | 8 | 90–110 | 52 62 72 78 115 | 10.51 | |

| EF | 50 | 6 | 110–132 | 50 55 65 70 102 | 10.51 | |

| JBC1160 | C | 180 | 13 | 110–132 | 115 135 150 180 200 260 | 15.5 |

| M | 130 | 10 | 110–132 | 100 110 120 135 165 175 | 15.5 | |

| F | 90 | 10 | 110–132 | 80 105 110 140 | 15.5 | |

| EF | 60 | 6 | 132–160 | 60 74 105 110 130 | 15.5 | |

| JBC1300 | C | 200 | 16 | 132–160 | 150 180 200 230 310 350 390 | 22.3 |

| M | 150 | 13 | 132–160 | 115 140 160 190 210 | 22.3 | |

| F | 102 | 10 | 132–160 | 90 115 145 160 | 22.3 | |

| EF | 70 | 8 | 185–220 | 88 110 135 155 | 22.3 | |

| JBC1400 | C | 215 | 19 | 185–220 | 200 220 260 350 420 440 | 26.3 |

| M | 160 | 16 | 185–220 | 155 180 200 220 | 26.3 | |

| F | 115 | 13 | 185–220 | 150 190 210 230 | 26.3 | |

| EF | 76 | 8 | 185–220 | 122 148 185 200 | 26.3 | |

| JBC1650 | C | 235 | 22 | 185–220 | 240 265 310 420 525 580 | 37.75 |

| M | 175 | 19 | 220–250 | 215 240 265 320 | 37.75 | |

| F | 130 | 13 | 220–250 | 180 210 235 255 275 | 37.75 | |

| EF | 90 | 10 | 220–250 | 148 178 200 220 | 37.75 | |

| JBC1680 | C | 267 | 22 | 250–315 | 330 390 525 655 725 | 51.5 |

| M | 203 | 16 | 250–315 | 230 270 300 330 | 51.5 | |

| F | 140 | 13 | 250–315 | 185 225 265 340 | 51.5 | |

| EF | 95 | 10 | 250–315 | 180 220 260 335 | 51.5 |

*Technical data is for reference only.

Why Choose Us?

-

1.Full Range of Equipment. Your One-Stop Source

We simplify your gravel & sand operations with full-process equipment from a single source, saving you time and effort.

-

2.Professional Service Guarantees Peace of Mind

Expert Maintenance Team + Genuine New Parts + Comprehensive Warranty for Stable, Continuous Production.

-

3.Transparent Inspection. Trusted Partnership

Check the interior conditions on-site. Buy with confidence.

-

4.Rich Experience

30+ years in the industry. Precise market insight,professional service.

-

QHow long does it take from order to delivery?

AFor equipment in stock, we can complete the internal inspection and loading within 7–10 working days. The sea freight duration depends on your destination port (e.g., 20-30 days to Southeast Asia or Africa). We will provide a clear timeline once the shipping route is confirmed.

-

QHow do I know the equipment is in good working condition?

APrior to shipment, we provide complete testing videos and live video inspections via WhatsApp or Zoom. This allows you to see the machine running in real-time. We also provide a set of high-resolution photos showing the critical components (motor, chassis, and wear parts) to ensure transparency.

-

QAre spare parts readily available for the equipment I purchase?

AWe understand that downtime is costly in mining operations. We offer a comprehensive spare parts support program for every machine we sell.

-

QWhat factors affect the price of a crusher?

AThe main criteria for judgment are based on a comprehensive assessment of factors such as the model, size, performance, and working efficiency of the crusher.

-

QSince you specialize in used machinery, can I customize or order a brand-new machine through you?

AYes, absolutely. While we are a leader in the secondary market, we maintain strong strategic partnerships with top-tier global manufacturers. We can facilitate the customization and procurement of brand-new mining equipment tailored to your specific project requirements. Whether you need specialized configurations or the latest models, our team can handle the entire sourcing and technical specification process for you.